What is carbon capture and storage?

Carbon capture and storage (CCS) is a process where this CO₂ is captured, compressed into a liquid and then stored in natural, underground reservoirs.

CCS is done to reduce greenhouse gas emissions, which accelerate climate change and global warming.

-

How is CO₂ captured and stored?

CO2 is generally captured from point-source emitters, such as electricity generation plants or large-scale processing plants (e.g. natural gas, fertiliser, steel or cement plants). Capture is achieved by a range of processes, such as using chemical sorbents, solvents and various types of membranes to separate CO2 from emission gases. The CO2 is then moved by ship or pipeline to an appropriate storage site, where the compressed CO2 is injected into a suitable geological structure (see diagrams below). The CO2 is stored as a liquid (supercritical phase) because it is denser and therefore more efficient to store than gas.

Reservoirs used for storage are typically at depths of 800 m or more underground and are usually in porous rocks such as sandstone overlain by a mudstone layer that seals in the CO2. The pore space in the reservoirs is normally filled with salty water (see 1 in the diagram). A variety of long-term monitoring systems, called monitoring and verification (M&V) technologies, are applied to ensure the safety and security of the stored CO2 for a long period of time.

Another option is to inject the CO2 into depleted oil or gas fields (see 4 in the diagram). Sometimes CO2 is injected into underground reservoirs to enhance or increase the recovery of oil (3 in the diagram), because the liquid CO2 flushes out oil that would otherwise remain trapped in small pore spaces underground. Typically, less than 50% of the oil in a discovery is recovered, but enhanced oil recovery (EOR) can sometimes increase this to 80-90%. EOR means more efficient use of known resources, reduced need for additional exploration and permanent storage of CO2.

-

Which parts of the world are using CCS?

To date, CCS has mainly been used in Europe, the USA, Australia and Asia, with a combined total of 28 operating commercial facilities. The first CCS plant, in Texas, USA, was operational in 1972. Since then, CCS has been used primarily to reduce emissions in natural gas processing facilities. However, only two of the facilities were capturing CO₂ from power generation in 2021 due to the large capital cost for capture facilities, issues with scaling up new capture technologies, concerns over safety and the lack of well-defined regulations. Currently, more than half of the 37 commercial facilities in construction or under development worldwide are for power generation and there is a growing global acknowledgment of the need to dramatically increase deployment of new power generation plants with CCS.

A range of approaches will be required to reduce global warming. Human-made emissions must be reduced drastically over the next few years if we want to reduce the risk of having extreme climate events and a significant rise in sea level. Other countries, such as the USA, have focused on substituting gas for coal in power stations (an example of ‘fuel switching’), which can halve emissions even without CCS. -

Why is CCS so important?

CCS has been proposed as a key technology to reduce global greenhouse gas emissions from fossil fuel power plants. It is also considered an important tool to enable countries to meet targets aimed at limiting global warming. In addition to energy generation from fossil fuels or biofuels, CCS can be applied to industrial processes that emit greenhouse gases, such as natural gas processing; hydrogen, cement, steel and aluminium production; and chemical manufacturing processes. It also provides an opportunity for developing nations to meet their increasing energy demand without the associated increase in greenhouse gas emissions.

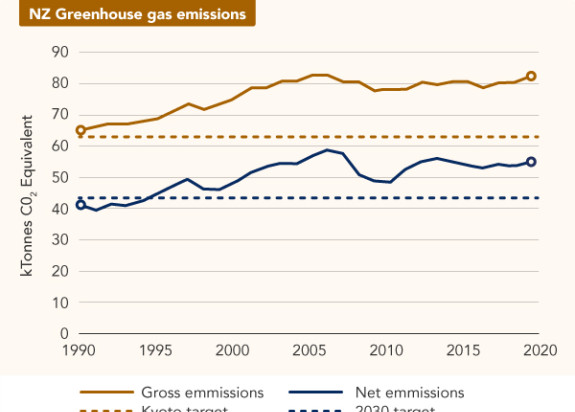

Aotearoa New Zealand has a unique emissions profile, dominated by agriculture and transport, with plans to phase out fossil fuel power generation by 2035. That means the opportunities for CCS in New Zealand are limited, particularly since retrofitting the capture of CO2 on existing plants is expensive. However, it does make sense to consider carbon capture technology associated with any new industrial development, potentially as a cluster or group of industries feeding CO2 into a national storage facility. A future energy strategy might include CCS with bioenergy generation (BECCS) or capturing CO2 directly from the atmosphere (direct air capture — DAC).

Geological storage also provides opportunities related to the underground storage of green hydrogen(external link) and the use of stored compressed air much like a large battery, as well as providing a key mitigation strategy during the transition to zero-carbon.

Will storing CO2 be enough to reduce emissions?

About 40 megatonnes (Mt) of CO2 are stored each year in CCS projects around the world. As an indication of what might be required, in their Sustainable Development Scenario (SDS), the IEA’s World Energy Outlook 2019 suggests the amount of CO2 captured and permanently stored each year needs to reach 2,800 Mt by 2050. Achieving this goal would require a doubling of global CCS capacity every five years from now through to 2050.

However, carbon capture and storage is only one tool available for reducing greenhouse gas emissions. The easiest and fastest approach is to use less fuel through conservation and efficiency. Transitioning to renewables such as geothermal, hydro and wind are also important and New Zealand is in the fortunate position of already utilising several renewable resources (our electricity generation, for example, is generally 80-85% renewable).