Advancing materials with Fisher and Paykel Appliances

We are working to significantly reduce the energy consumption and carbon footprint of appliances in New Zealand homes.

Building with better materials

Advancing the development and use of energy-efficient materials is pivotal to achieving a resilient, zero-carbon energy system. Rising to this challenge, GNS Science is working with technology leaders to meet the changing needs of our communities, industries, and government.

Working in partnership with technology leaders, we can bridge the gap between research and market application. These valuable relationships help us prioritise our research efforts, and inform practical science solutions that are useful, usable, and used by consumers and industry.

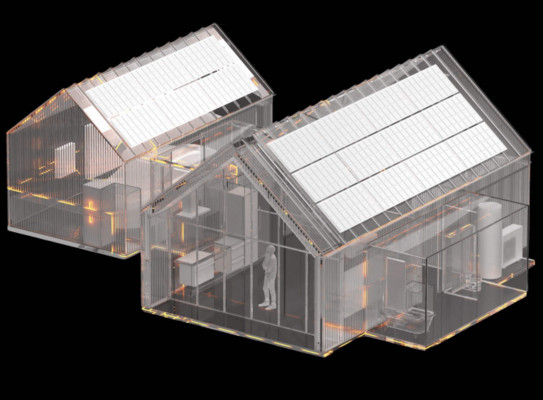

Fisher & Paykel Appliances (F&P) is demonstrating its commitment to de-carbonisation through its Carbon Zero SmartHome R&D Institute. It’s a connection point for experts from across the motu and the world to collaborate on technology and innovation needed to drive positive sustainable change.

With the help of NZ Product Accelerator (NZPA), F&P put out a call for help with its first ‘research challenge’ – making a step change in thermal insulation performance, with a view to decarbonising and increasing energy efficiency in Aotearoa New Zealand homes.

GNS Science’s in-house expertise was a vital component of this challenge. We are leading several different streams of work with F&P to investigate the fundamentals of heat-transfer, and to explore the application of those fundamentals to temperature controlled appliances that have reduced energy consumption and a lower carbon-footprint.

Work on the research challenge is supported by the NZPA and a wider research team of post-doctoral, PhD, Masters, and undergraduate students.

F&P’s Executive VP CarbonZero Transition and R&D, Kane Alwar says the project is a great example of the potential to extend F&P’s appliance knowledge and engineering innovation with GNS’ fundamental materials science expertise.

As part of our carbon zero goal, this ‘research challenge’ targets a 90% improvement in insulation effectiveness. It would enable 50% lower refrigerator and oven energy use and has wider potential across home construction and industrial insulation.

“We’re looking forward to more opportunities to partner with the research community and create the technologies we all need for a carbon zero future.”

GNS Science’s Project Lead and Energy Materials Scientist, Murray McCurdy says the breadth of the research and its possible applications is incredibly exciting.

This research spans the scales from placement of individual atoms through to appliance manufacturing. Alongside appliance innovations, it will lift our capability in New Zealand to deliver world-leading energy efficiency research.

In addition to the team’s focus on pursuing fundamental science breakthroughs, it is also seeking to apply the lessons as they go – enabling the project to generate short-term value while supporting the medium-and longer-term successes.